Polyjet 3D printing is a rigid photopolymer 3D printing method that produces parts by curing layer by layer of a liquid photopolymer until the part is formed. This 3D printing technology is highly accurate and is capable of multicolour and multi-material printing. To fully utilize the capabilities of Polyjet, special attention must be given to the first stage of the process: design.

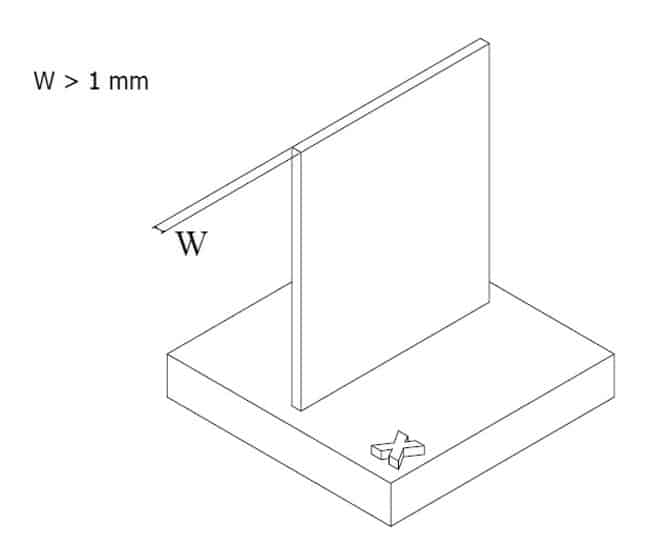

Volume, walls and feature size

Xometry Europe recommends the following sizes when designing for Polyjet 3D printing.

- Minimum wall thickness: While Polyjet 3D printing can produce thinner walls, we recommend a minimum wall thickness of 1 mm, irrespective of support, material type, or load expectations. The minimum thickness ensures that the wall is not only printable but can also withstand support removal, finishing, packaging, and shipping.

- Build volume: Xometry’s Polyjet printing partners can produce parts as big as 490 mm x 391 mm x 200 mm. For larger parts, the part can be split into different smaller parts that can be printed separately and assembled later on.

- Minimum feature size: On the other hand, our Polyjet 3D printing can produce features as small as 1.2 mm in any direction for rigid materials and 2 mm for their rubber like counterparts.

Tolerance

Polyjet is one of the most accurate 3D printing processes. This technology deposits layers with a thickness of 0.004 mm, far thinner than a sheet of paper. It produces tolerances of up to ±0.1 mm for the initial dozens of mm and ±0.05 for the ensuing mm.

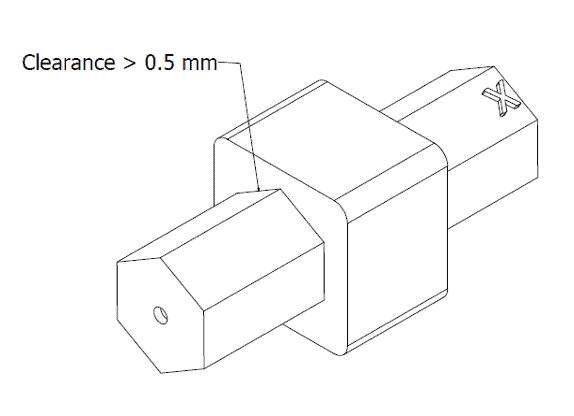

Interlocking features

Polyjet can print fully functional assemblies with moving mating parts. To prevent such parts from fusing during printing, we recommend leaving a minimum clearance of 0.5 mm between the parts.

Assemblies

Big or complex assemblies are usually printed as separate parts that are assembled after printing. The portions of the part’s that are to come in contact should be given a minimum tolerance of 0.6 mm. This is to accommodate friction, which CAD software programs don’t usually account for in perfect fitting 3D models. The clearance gives allowance for glue when creating assemblies by glueing parts together. We also recommended adding bumps and slots to flat mating surfaces to increase the integrity of the joint.

Support structures

Support structures are necessary when printing free-floating features and any overhanging geometry. Polyjet doesn’t have any self-supporting overhang angle. As long as there is an overhanging part, support structure is required. In Polyjet printing, support structures may be printed from a specially formulated, water-soluble material. This makes support structure removal as fast and easy as rinsing the part in water. Use support structures only when necessary, as the material can contribute significantly to the product’s final cost.

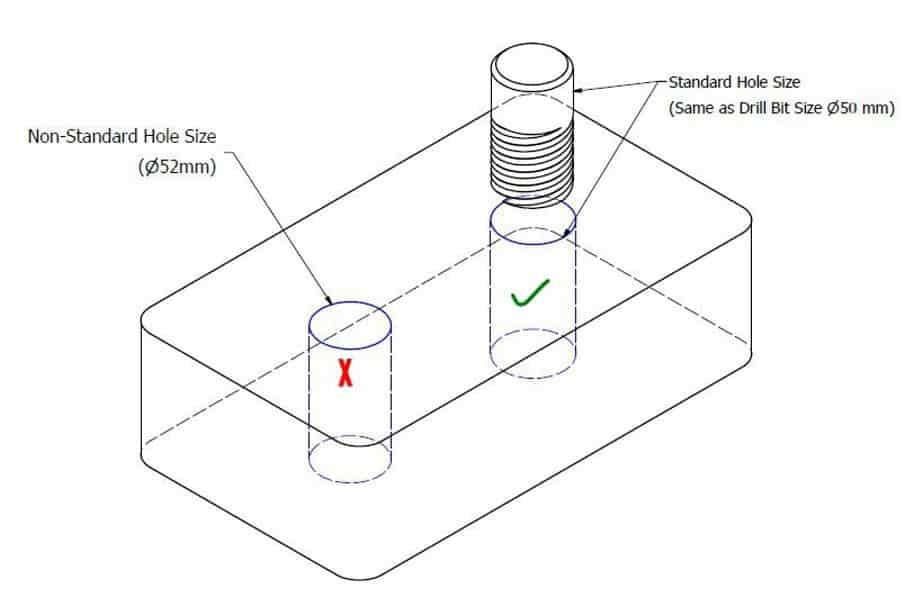

Holes and pins

Polyjet 3D printing is capable of printing holes. However, we recommend designing holes of standard drill diameters and drilling the holes after printing. When printing holes is vital, we recommend a minimum diameter of 0.5 mm. This diameter is also recommended for nonfunctional pins. For functional pins, use a minimum diameter of 2 mm. Another option is to use readymade off-the-shelf pins.

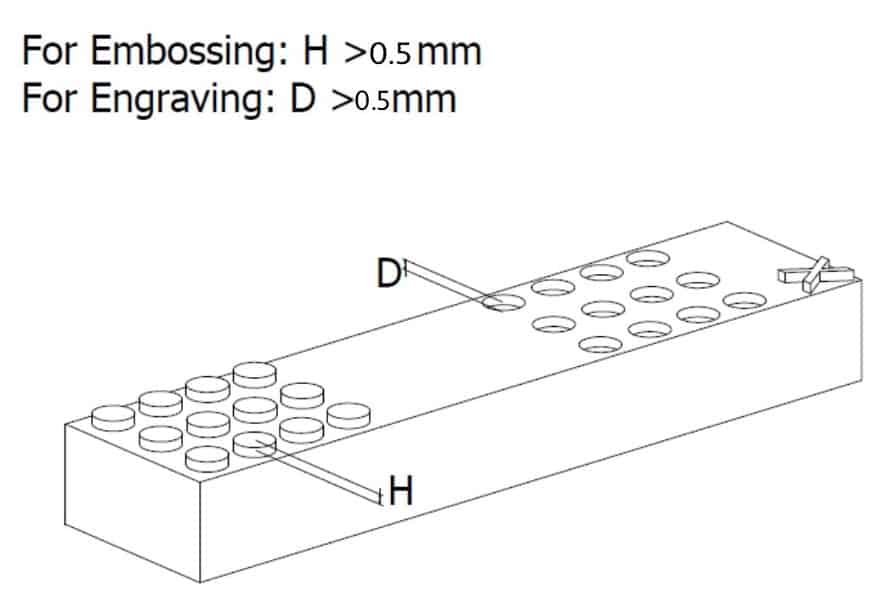

Embossed and engraved details

We recommend a minimum of 0.5 mm for both the depth and thickness of engraved details. On the other hand, a minimum thickness of 0.8 mm and a minimum height of 0.5 mm are recommended for embossed details.

CAD to 3D printing file format conversion

Designing for 3D printing doesn’t end with the preparation of the 3D CAD model. The conversion from the CAD file format to an appropriate 3D printing file format is a vital design consideration. STL is the most ubiquitous 3D printing file format. However, this file format only contains geometry data. Polyjet 3D printing is capable of multicolour and multi-material printing. To take advantage of this capability, use appropriate file formats such as OBJ and 3MF that are capable of storing geometry, colour, texture, and material data. Read more on the different 3D printing file formats and their characteristics

Conclusion

At Xometry Europe, we offer fast, reliable, and highly accurate Polyjet 3D printing services. Through our Instant Quoting Engine and our network of over 10,000 manufactures, we ensure that you experience a seamless part production process, from quoting to doorstep delivery.