CNC machining is widely employed across various industries for its high accuracy, precision, speed, and efficiency. However, CNC machining services can also be somewhat more expensive when compared to other manufacturing methods such as 3D printing. Cost is a crucial consideration in the application of CNC machining for both one-off or large scale production. This article highlights 10 tips through which you can significantly lower the cost of your CNC machined parts.

What Influences the Cost of CNC Machining

Before making any effort to lower machining costs, it is essential to first understand the factors that influence these costs in the first place. CNC manufacturing costs depend on the four following factors.

- Setup costs: These costs cover everything from CAD and CAM files preparation to process planning. Setup costs are fixed and are more significant for small production volumes.

- Material costs: The cost of the material from which a part is to be manufactured significantly affects the overall cost of the manufacturing process and the cost of the finished part. Rare materials drive up cost immensely. Machinability is also another material cost factor as it influences resource consumption and machining time and effort.

- Machining time: In the world of CNC machining, time is literally money. Machining time is a significant cost driver. The more time it takes to machine a part, the more expensive it will be. The costs involved in running and maintaining the CNC machine, energy consumption, and operator wages all increase as machining time increases.

- Miscellaneous costs: These costs in CNC machining cover anything that can be considered as special requirements or extra. These include tight tolerances, special tooling, closer quality control, and lower machining speeds.

Having understood the factors that drive costs in CNC machining, we can now explore the ways by which they can be reduced.

10 Tips to Reduce the Cost of a CNC Machined Part

Analysing the major factors that influence the cost of CNC machining, there are three major ways to lower it. These are design optimisation, material selection, and special considerations, with design optimisation being the most important. The following are ten ways by which you can significantly reduce CNC machining costs.

1. Material selection

Before selecting a particular material, carry out extensive research to ascertain that it is the least expensive option that has all the required properties for your application. While material quality shouldn’t be compromised, not all the properties of a material are needed for a particular application. For example, heat-resistant steel is an unnecessary, costly choice for machining a whistle.

Another important material consideration is machinability. Certain materials, such as aluminium, have high machinability and should be used whenever possible. Different aluminium alloys also differ in price. For example, one part below, made from rarer Aluminium 3.1645, would cost 25% higher compared to Aluminium 3.3206.

2. Avoid multiple finishes

CNC machining typically produces a satisfactory as-machined surface finish. This finish should be selected whenever possible as multiple surface finishes, though a necessity for some parts, cost more to apply. Surface enhancing finishes such as anodising and Chem film should only be requested when necessary. Another severe cost driver is applying different surface finishes for different areas of a part. An example of this is applying bead blasting in one area and a Chem film in another. Try to keep any finishing specifications uniform to the whole part.

3. Order in bulk

Economics of scale applies significantly to CNC machining. The price of machining exponentially reduces as production volume increases. To put the cost savings into perspective. A single unit of the part in the image below costs €30.75. The cost per unit drops to €9.62 for a production volume of 10 parts, and €6.76 for a production volume of 100 parts. These drops are because the setup cost stays the same, whether you are producing one unit or 100 units of the same part. Bulk orders also eliminate the cost of different machine setups as the same settings will be used for the entire production. Always take advantage of the economics of scale by placing bulk orders.

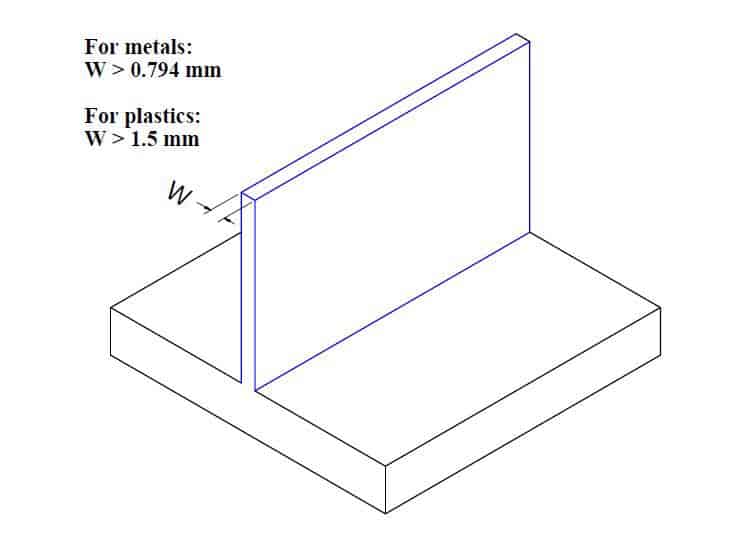

4. Avoid Excessively Thin Walls

Thin walls take more time to manufacture. This is because they are fragile and require multiple passes at low cutting depth. They are also very likely to vibrate, and so machining them to specified tolerances is challenging and time-wasting. This increases machining time and, by implication, machining cost. To avoid this cost, design thicker walls. We recommended a minimum wall thickness of 0.8 mm for metals and 1.5 mm for plastics.

5. Round Internal Edges with Sufficient Radius

Because cutting tools are cylindrical, it is impossible to machine perfect 90° internal corners. The only way to achieve this is via EDM, which is a much more expensive manufacturing process than CNC machining. We highly recommend that you round all interior edges in your design, as this will save the time it will take the cutting room to attempt to produce sharp edges. We also recommend a sufficiently sized radius of at least 1/3 times the depth of the cavity. A small corner radius would require a tool with a small diameter, and because small tools cannot remove large amounts of material in one pass, multiple passes at slower speeds will be required, thereby increasing machining time and cost.

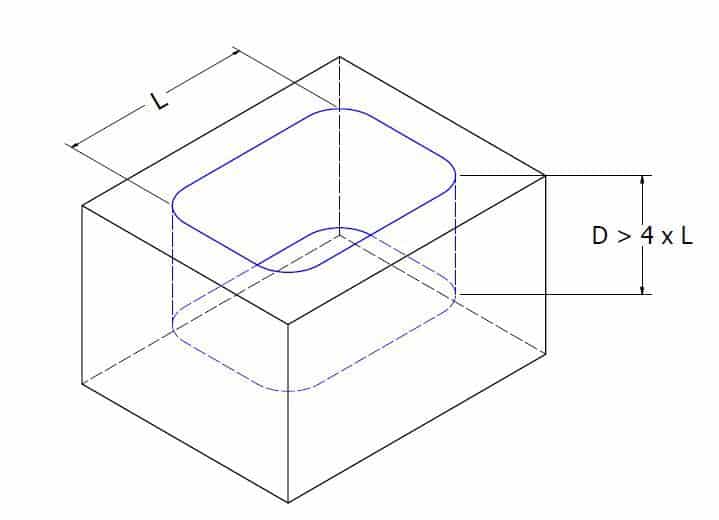

6. Don’t Design Deep Cavities

Deep pockets/cavities involve a lot of material removal to create, making them time-consuming features. Machining them can also result in tool hanging, tool deflection, and tool breakage. The only way to avoid these tool problems is to progressively step down the end mill. However, this is also immensely time-consuming.

A simple way to avoid all of these is to design cavities with a minimum depth of four times their width. For example, a 10 mm wide cavity should not be deeper than 40 mm. Note that any cavity deeper than six times the diameter of the cutting tool is considered deep.

7. Limit the Depth of Threads

Threads provide very reliable connections. However, the strong thread connections occur in the first few threads, making long threads unnecessary. Long threaded holes may involve special tools and require more time and effort to machine. Always limit the depth of threads to a maximum of three times the hole diameter. When threading a blind hole, we recommend adding an unthreaded length of at least half the hole diameter at the bottom of the hole.

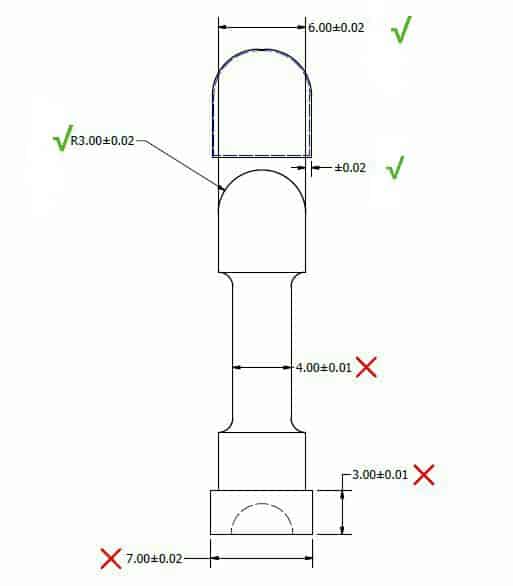

8. Specify tolerances only when necessary, avoiding tight tolerances

Tolerances typically drive up machining cost and time and should only be specified when necessary. CNC machines are highly accurate and produce standard tolerances when custom tolerances are not specified in the design. Tight tolerances should be specified only when necessary, as they are challenging to apply. They also require more machining time and manual inspections. We also recommend that you use GD & T in your drawings and they define looser tolerances.

9. Use standard hole sizes

When designing holes, utilise standard drill bit sizes. Non-standard hole sizes would require end mills to finish the hillside to the specified non-standard dimension, significantly increasing machining time.

10. Don’t include lettering in the design to be machined

Machining texts on parts in an unnecessary cost driver, requiring extra time and effort to create. Required texts can be painted on the finished part after manufacturing. If it’s necessary to include texts, then utilise engraved texts, as these involve less material removal.

Conclusion

By following these tips, you can significantly reduce the cost of CNC machined parts. At Xometry Europe, we offer fast, affordable, and reliable CNC machining services, whether for one-off productions or large production volumes. Head over to instant quoting platform to upload your optimised models and select the best materials for your application.