The application of 3D printing in the medical industry has led to colossal innovations, discoveries, and industry growth. This manufacturing process, once considered novel, is now indispensable and widely used in the medical industry. 3D printing has numerous characteristics that are immensely crucial and beneficial in the medical industry. Some of these are speed, versatility, the ability to work with various materials, customisation, repeatability, and the ability to manufacture highly complex parts.

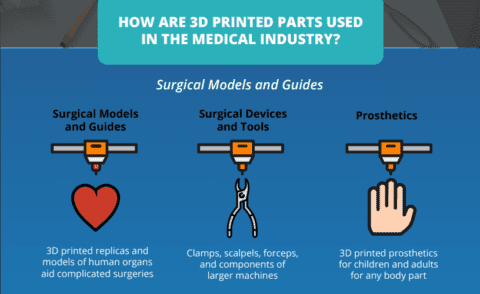

The applications of 3D printing in the medical industry include the manufacture of custom prosthetics and orthodontics, implants, custom anatomical models for surgical preparation, anatomical study models, medical aids, prototypes, medical tools, and general medical equipment.

Requirements for materials to be used in the medical industry

3D printing is a broad manufacturing technology that is compatible with numerous plastics, elastomers, and metals. However, not all 3D printable materials are suitable for use in the production of medical products. They are certain characteristics that materials must possess to be ideal for the medical industry. Some of the required properties of medical 3D printing materials are as follows:

Biocompatibility: Materials that are used to create products such as implants and internal medical devices must be biocompatible. This means that they must be completely unreactive when in contact with a biological system. Biocompatibility is crucial for implants, dentures, organ/bone replacement, pacemakers, and other medical products that contact human tissues.

Sterilisability: The extremely high sanitary demands of the medical industry make sterilisation is critical in most cases. This makes sterilisability a vital property of medical 3D printing materials.

Bio Usability: For body part replacement such as prosthetics, dentures, implants, and artificial organs, it is not enough for the materials to be biocompatible. They also need to possess similar physical properties with the original body part. For example, bone replacement materials have to be hard and strong, with high compressive strength. Likewise, a material to be used in printing a human ear would have to be relatively soft.

Note the required characteristics may vary based on the application of the product to be manufactured.

PA 12 (Nylon)

This is a highly versatile lightweight, corrosion-resistant, and chemical resistant material. It is also tough and flexible with high tensile and impacts strengths. Nylon PA12 can be sterilised using ethylene oxide, chemical, gamma irradiation, gas plasma, and steam autoclave. It is printed using MJF or SLS 3D printing. As a medical-grade material, Nylon PA12 is ISO certified and USP Class I – IV and is commonly used in prosthetics.

ABS M30i

ABS M30i is another widely used thermoplastic in the medical industry. In addition to being biocompatible, it is also sterilisable using gamma irradiation, ethylene oxide, and gas plasma. ISO certified and USP Class I – IV, this material is often used to produce medical equipment and detailed anatomical models. It may also be used for prosthetics. ABS M30i is tough and has high tensile and impact strengths. It is printed using FDM.

PC ISO

This material is commonly used to create moulds, prototypes, and custom surgical guides. While PC ISO has a lesser quality finish than Nylon PA12, it is strong and heat resistant with high tensile strength. PC ISO is also biocompatible, albeit short term, and can be sterilised via gamma irradiation and ethylene oxide. PC ISO is printed via FDM.

Polyetherimide (ULTEM 1010)

Compared to other FDM thermoplastics, ULTEM 1010 is one of the strongest and most resistant to heat and chemicals. It is also highly biocompatible and can be sterilised using gamma irradiation, ethylene oxide, gas plasma, and steam autoclave. ULTEM 1010 is used to print surgical guides, prototypes, and prosthetics.

PPSF

This FDM material is known for its heat and chemical resistance and its desirable mechanical properties. It is biocompatible and can be sterilised using steam autoclave, ethylene oxide, gas plasma, and gamma irradiation. These properties make PPSF excellent for producing prosthetics, prototypes, and parts to be used in high load or high-temperature applications.

Silicone (Sil 30)

Silicone is heat resistant, tear-resistant, and highly flexible biocompatible elastomer. It is commonly used in the manufacture of wearables with skin contact, such as respiratory masks. It may also be used to print implants. Silicone can be printed using Carbon DLS 3D printing.

Titanium (Ti6Al4V)

Titanium is one of the most ubiquitous metals in the medical industry. The high preference for this material results from its numerous beneficial properties and likeness to the human bone. Titanium is extremely strong, heat resistant, hard, corrosion-resistant, non-reactive, sterilisable through various methods, and highly biocompatible.

This material is widely used in the medical industry to manufacture custom orthopaedic implants such as bone and joint replacements, dental implants, and cranial plates. It is also used to create medical tools. Titanium is printed using DMLS.

Cobalt chrome (CoCr28Mo6)

Like titanium, cobalt chrome is widely used in the medical industry to manufacture orthopaedic implants such as replacement teeth, bones, and heavy use joints, such as hips, shoulders, and knees. Cobalt chrome is biocompatible and highly resistant to heat, corrosion, wear, and chemicals. It also has high strength and hardness and is relatively lightweight. Parts are printed from this material using direct metal laser sintering.

Stainless steel (17-4PH)

Stainless steel is a high strength metal that is biocompatible and can be sterilised via various sterilisation methods. However, its corrosion resistance is short-term, making it less preferable than titanium and cobalt chrome, especially for implants. This material is great for surgical tools and temporary implants. Stainless steel is also cheaper to print using DMLS, than titanium and cobalt chrome.

Conclusion

At Xometry Europe, we offer fast, reliable, and highly accurate 3D printing services for thermoplastics, elastomers, and metals that are of immense benefit to the medical industry. We also offer various post-processing operations to ensure the utmost quality.

Regardless of quantity, precision, complexity, and required delivery time, we always have the manufacturing capacity to deliver. Head on to our instant quoting platform to upload your models and receive a quote in seconds, absolutely free.

Read more about the use of 3D printed plastics in the medical industry in our infographic.